An Introduction to Infrared Thermography

Infrared thermography, a cornerstone of modern infrared inspection, stands out as a non-invasive diagnostic tool, revolutionizing the approach toward preventative maintenance and safety inspection. Utilizing state-of-the-art infrared cameras, this technology makes the invisible visible by capturing the heat emitted from objects in vivid colors, revealing potential issues in electrical systems, insulation failures, and even hidden moisture problems that could lead to structural damage or safety hazards. It’s this ability to detect subtle temperature variations that positions infrared thermography as an invaluable asset in the field of building inspection and maintenance.

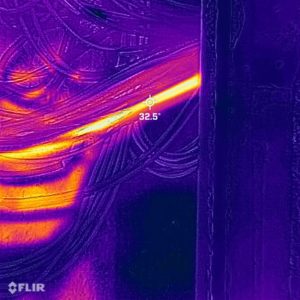

For example, the image below on the left taken by a thermal camera shows wiring within an electrical panel that is overheating. The image below on the right shows a conduit that is warmer than the surrounding conduits due to overheating wires within.

The Role of Thermographic Inspection Services

Thermographic inspection services extend beyond simple identification of temperature discrepancies. They represent a key tool in a comprehensive analysis of a building’s thermal performance, identifying potential energy losses, moisture intrusion, and areas of insufficient insulation. By employing advanced thermographic imaging techniques, inspectors can pinpoint areas of concern that are often overlooked by traditional inspection methods, offering a clear roadmap for targeted repairs and improvements.

Preventative Maintenance Through Infrared Inspection

The essence of any effective electrical maintenance program lies in its ability to foresee and forestall potential system failures. Infrared thermography excels in this arena, especially concerning electrical systems where the early detection of hotspots can prevent overloads, short circuits, and even fires. Regular infrared inspections can uncover hidden issues such as electrical imbalances, overloaded circuits, and faulty wiring. By addressing these problems promptly, businesses and building owners can avoid the costly downtime associated with major repairs, ensuring that electrical systems are not only efficient but also compliant with Florida’s ever-growing safety standards and expectations.

Observing the Invisible: Enhancing Safety with Infrared Thermography

Beyond maintenance, infrared thermography offers an unparalleled advantage for safeguarding properties and their occupants. By revealing abnormal heating patterns across electrical panels, machinery, and building envelopes, this technology aids in the early detection of conditions that could lead to catastrophic failures or fire hazards. Furthermore, in the context of building inspections, infrared thermography provides a non-intrusive means to assess the condition of critical infrastructure without disrupting operations, making it an ideal solution for busy commercial facilities and residential complexes alike.

Application in Building Safety Inspection Programs

In regions prone to high heat and humidity like Florida, Building Safety Inspection programs mandate regular inspections. Infrared thermography adds a critical layer of scrutiny, identifying issues that could compromise structural integrity that could otherwise be missed. As a certified Level 2 infrared thermographer (#16287), my role involves conducting thermographic inspection services to provide a comprehensive analysis of electrical systems beyond what is visible to the naked eye.

Incorporating infrared thermography into safety inspection programs enhances inspection thoroughness and offers tangible benefits, including cost savings, energy efficiency, and improved risk management. It empowers building owners and facility managers with the insights necessary for making informed decisions, thereby ensuring the longevity and safety of their properties.

Our Final Thoughts

Infrared thermography offers an indispensable advantage in maintaining the integrity, safety, and efficiency of your building’s electrical systems. By leveraging advanced infrared inspection and thermographic inspection services, we’re not only able to detect potential issues before they become costly repairs but also ensure the safety of occupants and the longevity of your property’s infrastructure.

At Building Mavens, we’re committed to providing top-tier inspection services that adhere to the highest standards of safety and quality. If you have any questions about how infrared thermography can play a role in your next building inspection, or if you’re interested in learning how our infrared thermography service and related inspection and engineering services can help keep your building safe, please don’t hesitate to contact us. Let us assist you in safeguarding your investment and ensuring a safer, more secure future.

About the Author

Contact me for more information: nick@buildingmavens.com